Products

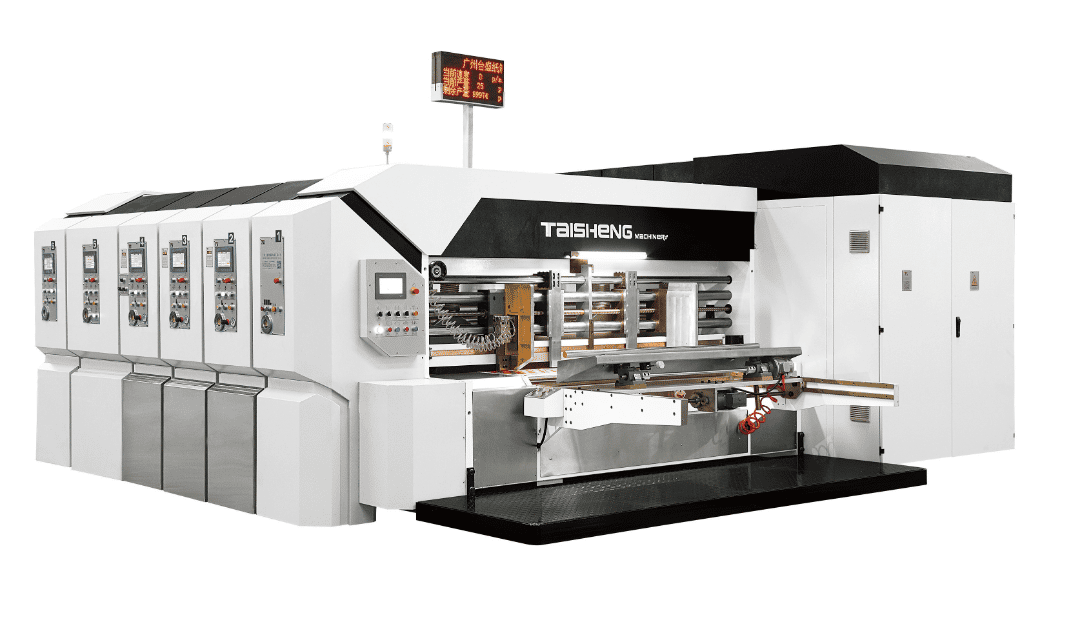

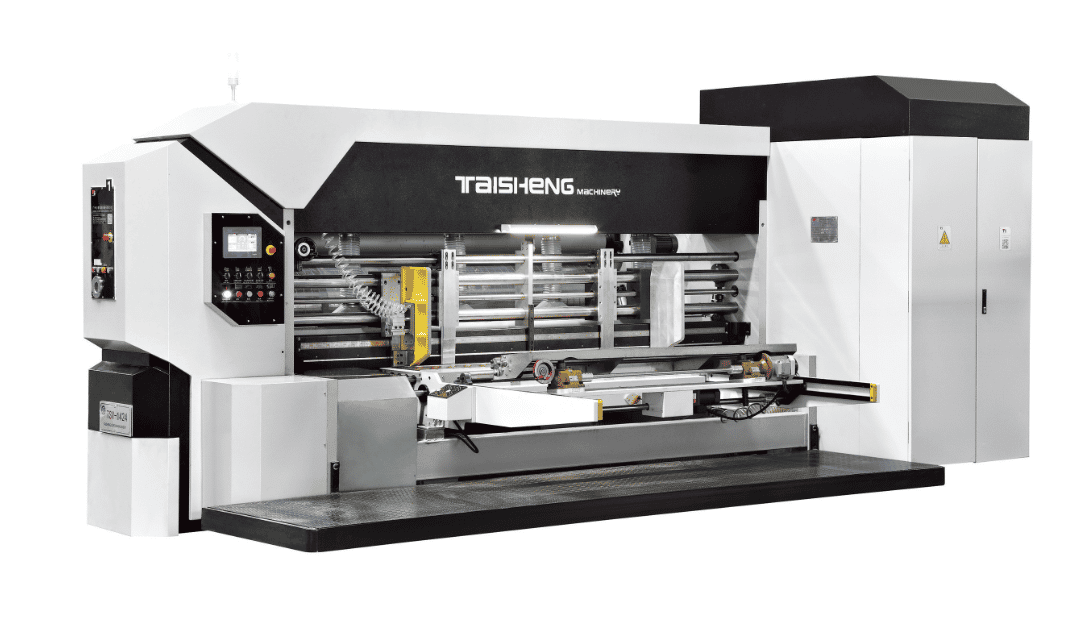

TSG2-Whole vacuum transfer high speed corrugated carton machine

Original Region :

GUANGZHOU,CHINAPayment :

T/T,L/CShippingPort :

GUANGZHOU/SHENZHEN

TSG-2 WHOLE VACUUM TRANSFER HIGH SPEED PRINTER SLOTTER DIE CUTTER

MACHINE (FULL COMPUTER CONTROL)

Performance Characteristics of The Whole Machine

|

Model |

TSG-2S-920 |

TSG-2S-1224 |

TSG-2S-1424 |

TSG-2S-1628 |

|

Max. Machine Speed (pcs/minute) |

250 |

200 |

180 |

150 |

|

Max. Feeding Size (mm) |

900×2000 |

1200×2400 |

1400×2400 |

1600×2800 |

|

Jump Feed Max. Cardboard Size(mm) |

1200×2000 |

1500×2400 |

1700×2400 |

1900×2800 |

|

Min. Cardboard Size(mm) |

300×600 |

365×600 |

400×600 |

450×600 |

|

Max. Printing Size |

900×1960 |

1200×2360 |

1400×2360 |

1600×2760 |

|

Min Slotter Blade Space(Male)(mm) |

150×150×150×150 |

150×150×150×150 |

150×150×150×150 |

150×150×150×150 |

|

Min Slotter Blade Space(Female)(mm) |

240×65×240×65 |

260×65×260×65 |

260×65×260×65 |

260×65×260×65 |

|

Max Slotting Deep(mm) |

250 |

300 |

350 |

400 |

Feeder Unit

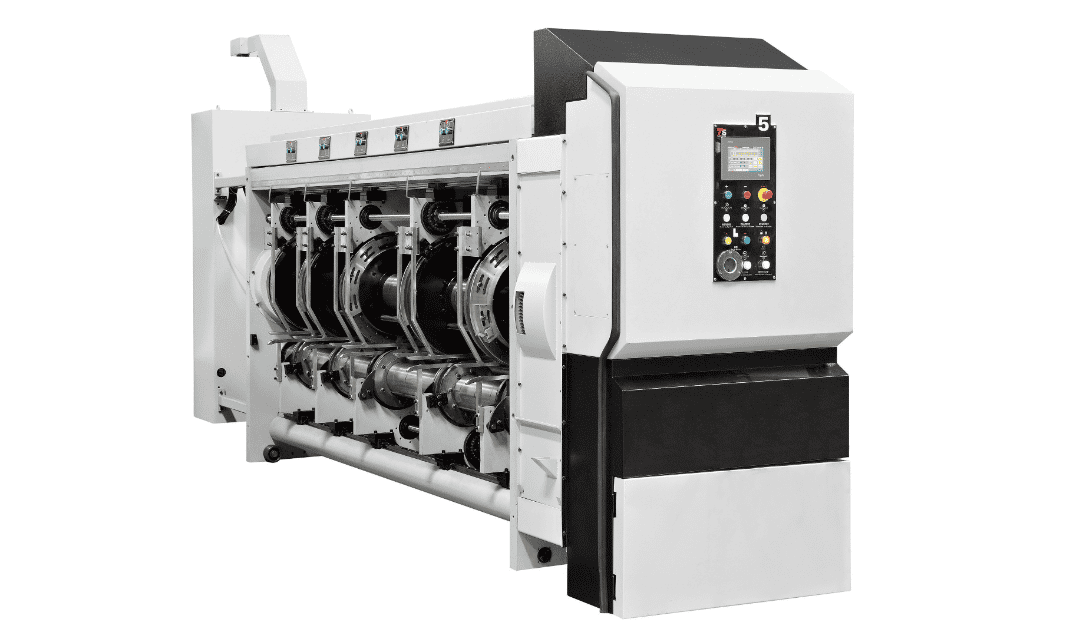

Slotter Unit

Die cutter Unit Unit

Guangzhou Taisheng Carton Machinery Co., Ltd. is located in the machinery manufacturing industry developed, convenient transportation, Guangzhou Huadu District, east of Baiyun International Airport,

Add : NO. 20 Yayao Middle Road, Yayao Town, Huadu District, Guangzhou City, China

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright 2025@ GUANGZHOU TAISHENG CARTON MACHINERY CO .,LTD All Rights Reserved.

Sitemap

| Blog

| Xml

| Privacy Policy

Network Supported

Network Supported